- Is the mushroom the next big thing in luxury fashion accessories? San Francisco start-up MycoWorks makes leather from mycelium and is set to open its first commercial-scale plant in September

- MycoWorks’ customers include Hermès, Ligne Roset and General Motors, while another start-up called Ecovative is making mycelium-based bacon, textiles and packaging

The humble mushroom could be the next must-have accessory.

The San Francisco start-up MycoWorks makes leather from mycelium – the weblike fungus that can become a mushroom – and it’s set to open its first commercial-scale plant in September in South Carolina.

The factory will produce millions of square feet of mycelium a year, MycoWorks said. Customers include the luxury brand Hermès, the high-end home furnisher Ligne Roset, and General Motors, which is exploring the use of leather alternatives for its vehicles.

“The commitments we have from these partners enabled this factory to be built,” Matt Scullin, the CEO of MycoWorks and a materials scientist, told us. He added that the factory will help the company penetrate the fashion and luxury industries “in a real way”.

Reishi Natural elevates fine mycelium’s distinctly natural beauty. Photo: @mycoworks/Instagram

Many fashion brands have set climate goals and are searching for sustainable substitutes to animal- or plastic-based leather and other textiles with high carbon footprints. The brands’ push has spurred investment in more than 100 start-ups developing these alternatives, according to the Material Innovation Initiative, an industry think tank.

Start-ups focused on so-called next-generation materials raised some US$457 million in 2022, though that was a drop from 2021 in part because of higher interest rates.

MycoWorks’ shift to a commercial-scale operation has been decades in the making, Scullin said. The company has raised US$187 million in funding, a spokesperson told us.

Yet even with MycoWorks’ milestones, the new production will only account for a sliver of the estimated 23 billion sq ft of leather produced globally each year, much of which is used for footwear.

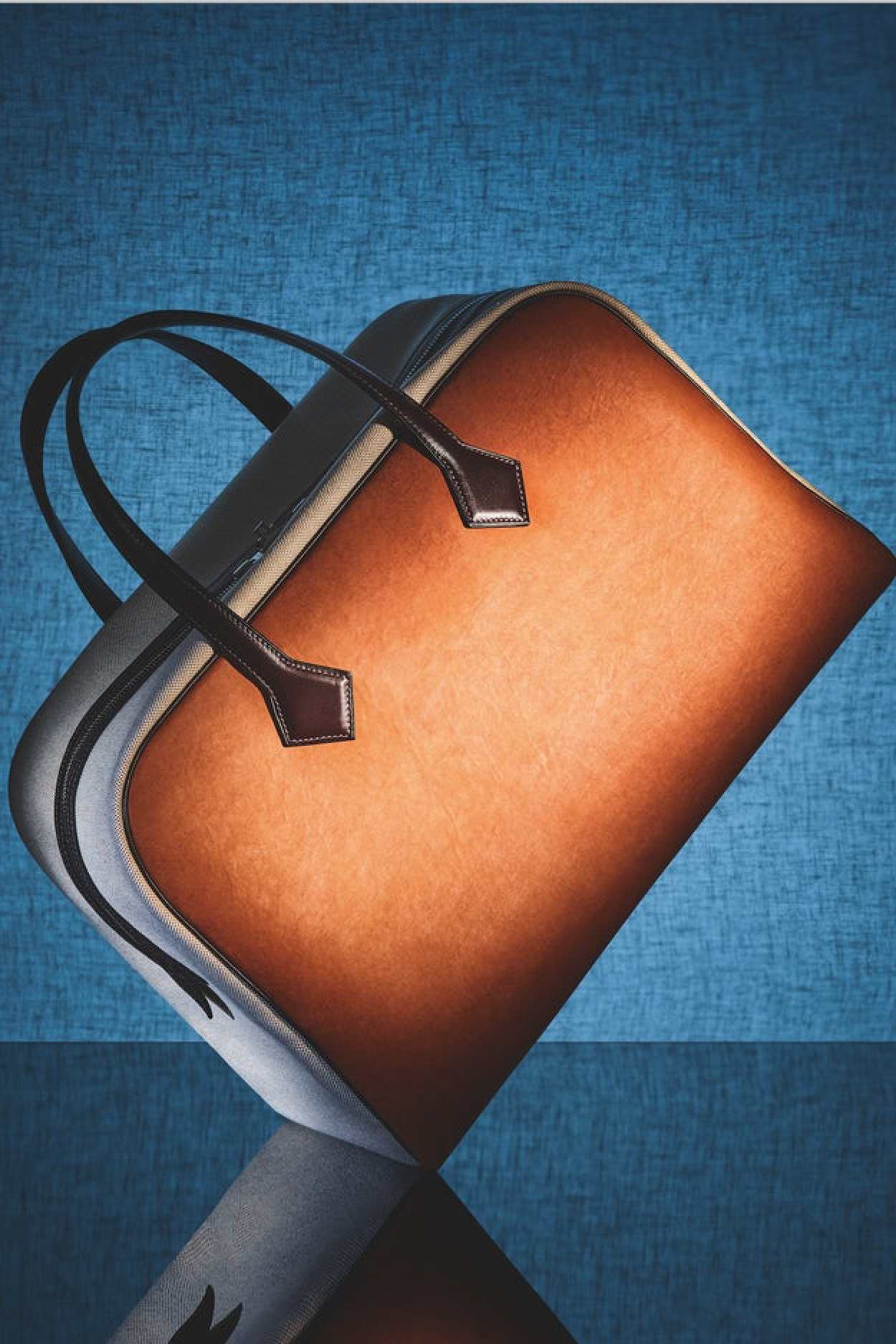

Hermès Victoria bag made with Sylvania, a leather alternative developed from MycoWorks’ patented fine mycelium. Photo: Hermès

The alternative-materials industry still faces headwinds. Bolt Threads halted production of its alternative leather, made from mycelium and minimal plastics, this year even after landing high-profile partnerships with Stella McCartney and Adidas and raising more than US$300 million since 2009. CEO Dan Widmaier told Vogue Business that funding had dried up but the company is open to selling the technology to make sure its material gets to market.

Yet such challenges haven’t deterred all investors. A start-up called Ecovative that’s making mycelium-based bacon, textiles and packaging recently said it attracted more than US$30 million in a funding round.

Anne Higonnet, an art history professor at New York’s Barnard College who teaches a popular course on clothing and the rise of sustainability, told us that most technological advances in fashion have required loads of capital and experimentation. She sees a luxury fashion house like Hermès as an ideal pioneer for alternative leather because the brand’s status is based in part on scarcity.

The Made with Reishi capsule collection by Allen St. Photo: @mycoworks/Instagram

“Hermès makes the single most desirable handbag on the planet – the Birkin – with legendary wait times,” Higonnet said. “The hope is that with their approval and financing, experimental companies can slowly scale up and produce viable leather substitutes that eventually wean us off of both leather and plastic simultaneously.”

Scullin sees a future where MycoWorks’ material, called Reishi, is available beyond the luxury market. He said Reishi is different from its competitors for two reasons: its quality and production process that grows sheets of mycelium in small trays.

Source : SCMP